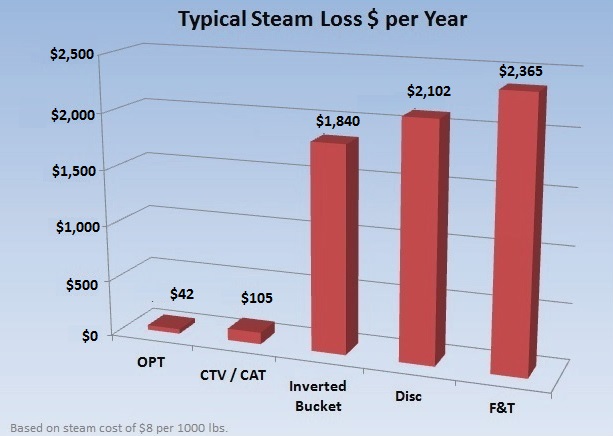

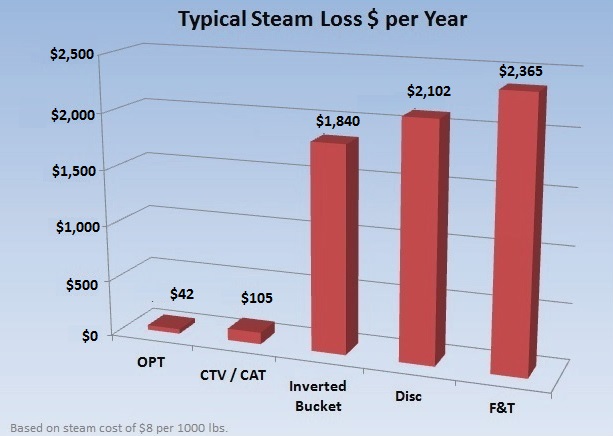

The Ogontz TL valve is a fully self-contained, temperature-actuated control valve. It effectively eliminates steam waste by automatically regulating the supply of steam in response to changes in ambient temperature. As a result, the TL valve achieves dramatic reductions in the amount of steam consumed, with annual savings averaging eight times its installed cost. High reliability, low maintenance and long service life are assured by the state-of-the-art, precision thermal actuator. The TL valve completely eliminates the use of hazardous, chemically filled diaphragms, delicate capillaries or thin-walled bellows. The TL valve continuously monitors ambient temperature, and regulates steam flow on an as needed basis. This eliminates steam waste and substantially reduces the possibility of overheating. The TL valve is ideal for steam-traced lines of all types, protecting temperature sensitive instrumentation, winterizing product lines, conserving energy in unit heaters, and other applications requiring control of heat transfer media (i.e. glycol, hot oil, water, etc.) based on ambient temperature change. The TL ambient sensing valve is the key to positive, year-round protection of your systems and equipment at the lowest cost.Design Features

Design Features

Design Features