Valve Type |

N/A ST Temperature Sensing Control Valve |

NPT Thread Size |

N/A 1/2 in |

Full Open Set Point Temperature Range |

N/A 35 to 240 ºF |

Maximum Operating Pressure |

N/A 200 psig |

Body Rating |

N/A ANSI 300 lb. class |

Orifice Size |

N/A 1/2 in |

| Flow Coefficient (Cv)1 | N/A 3.4 |

Valve Action |

N/A Direct |

Maximum Capacity of Saturated Steam at 15 psig Inlet Pressure |

N/A 186 lb/hr |

Maximum Capacity of Saturated Steam at 30 psig Inlet Pressure |

N/A 280 lb/hr |

Maximum Capacity of Saturated Steam at 50 psig Inlet Pressure |

N/A 405 lb/hr |

Maximum Capacity of Saturated Steam at 100 psig Inlet Pressure |

N/A 718 lb/hr |

Maximum Capacity of Saturated Steam at 150 psig Inlet Pressure |

N/A 1030 lb/hr |

Maximum Capacity of Saturated Steam at 200 psig Inlet Pressure |

N/A 1343 lb/hr |

Body Material |

N/A Stainless Steel |

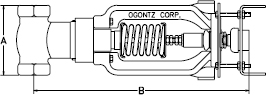

Dimension A |

N/A 4 in |

Dimension B |

N/A 11-5/8 in |

Dimensional Drawing |

N/A

ST/STE Schematic Figure 2 |

Net Weight |

N/A 8.5 lb |

Note |

N/A 1 1/4" NPT female connection required to mount STE valve into well Optional matching length 316 SS well, order part number 3402997 (well external threads 1 1/2" NPT) STE standard extension length is 6" STE standard extension material is brass (stainless steel available – consult local distributor) Valves supplied with heat conductive compound |

The Ogontz Guarantee |

N/A We will repair or replace on a no-charge basis, F.O.B. Willow Grove, PA, any Ogontz product returned to us within 18 months, if found to be defective in material or workmanship. |

STE Well Extension Length Range |

N/A 6 to 72 in |